Biogas is probably the best kept secret in the renewable energy industry.

Organic waste is one of the untapped sources of natural energy available today. “It's a simple solution that can be deployed in as quickly as three days but people don't know too much about it”, says Jonathan de Magalhães, Managing Director of Ubuntu Energy Solutions. While biogas is used all over the world --India for example has more than 4.5 million digesters–harnessing biogas energy in South Africa is practically unknown. Only a small number of digesters have been built successfully and commissioned to date – a loss to the renewable industry sector in the country since biogas fulfils all of the criteria relating to environmental sustainability, requires a relatively low technological input and is cost effective to implement.

Biogas typically refers to the gas which is produced by the biological breakdown of organic matter. Organic waste, such as dead plant matter, animal manure and kitchen waste, can easily be converted into biogas in a simple biogas digester. Biogas consists mainly of methane (CH4) and carbon dioxide (CO2). Biogas can be used as fuel for cooking, lighting, water heating as well as being able to run biogas generators to produce electricity.

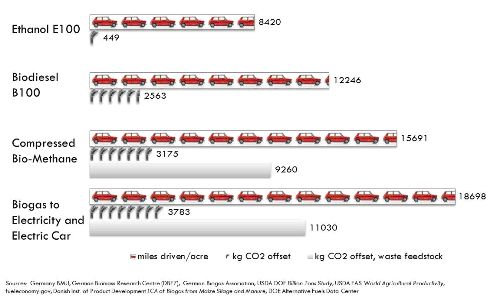

Biogas provides a clean, easily controlled source of renewable energy from available organic waste for a small labour input, replacing firewood or fossil fuels, which are becoming more expensive as demand outweighs the supply.

Additionally, a biogas digester treats the organic waste and prevents it from taking up precious space in our landfills or over-burdened sewerage plants. In South Africa the waste disposed of in landfills produces unwanted landfill gas (Methane CH4) and leachate emissions. Furthermore, there is pressure on the country's aging sewerage system. According to de Magalhães, generating biogas presents a Win-Win -Win solution because it offers:

Easy disposal and treatment of Organic Waste

- Black Water Treatment: By feeding the black water (sewerage) into the biogas digester, additional organic waste as well as much needed water, will increase the yield of biogas from the digester daily. Additionally, in environments that would normally require a septic tank system, the cost saving of not needing the septic tank can be used to offset the costs of the biogas system.

- Organic waste, such as grass cuttings, animal manure, kitchen waste and almost any other type of similar waste, can be used to generate a usable form of energy.

- As the biogas digester is a closed system, there is no leakage of the organic waste into the surrounding environment. This can significantly reduce, or even eliminate, the need for an Environmental Impact Study.

Reduction of associated Energy Costs

- The biogas generated by the digester system can be used for water heating, space heating, cooking, lighting or running a biogas generator for electricity generation. Or any combination of these.

- By using biogas instead of traditional resources, such as electricity or gas, to provide this functionality, energy costs can be significantly reduced, providing a quick Return on Investment (ROI) for biogas solutions.

Provides further Cost Savings or a Passive Income

- As the process of biogas generation uses the bacteria in the organic waste, the organic slurry found at the end of the process can be easily managed, and all organic smells are contained within the closed digester system. This organic slurry can be used as a natural fertiliser for nearly all agricultural applications, reducing any costs associated with purchasing traditional fertilisers.

- This 100% natural organic fertiliser can also be sold to agricultural farms and nurseries, either in its liquid form or pre-dried and pelletized, providing an additional form of income from the biogas digester.

Biogas digesters are used all over the world, and the technologies have made leaps and strides, especially over the past three years. The first biogas system was installed in India in 1859. South and south-west Brazil are characterised by intensive livestock farming. Rio Grande do Sul, the southernmost Federal state in Brazil, has an abundance of pig farms. The manure produced in large quantities by pig farming is used for biogas production.

According to de Magalhães, generating biogas offers a better Return on Investment (ROI) than solar or wind systems. “It's easy to install and deploy, and is very low in maintenance, probably only requiring some attention once every 5 to 7 years. For these reasons, biogas digesters would work well in rural villages, farming communities and game lodges,” says de Magalhães.

But even the average family in Johannesburg could use their organic household waste in a biogas system. “As long as you have enough feedstock to put into the biogas system, such as blackwater, grass cuttings, and a reasonable amount of kitchen waste, then you can generate your own biogas. Even with a small system with enough organic feedstock, combine this with some solar panels and an intelligent inverter system, and you could get about 80% off the grid, all things considered.” says deMagalhães.“There is no smell because it is a closed system, and the payback period could easily be under 10 years, which is much shorter than a solar-powered system.”

However, amidst all these advantages, there have been no government initiatives in South Africa to assist those wishing to deploy biogas systems.

To learn more about biogas technology, be sure to attend the annual Africa Energy Indaba being held from February 21 to 23, 2012 at the Sandton Convention Centre in Johannesburg.

.jpg)